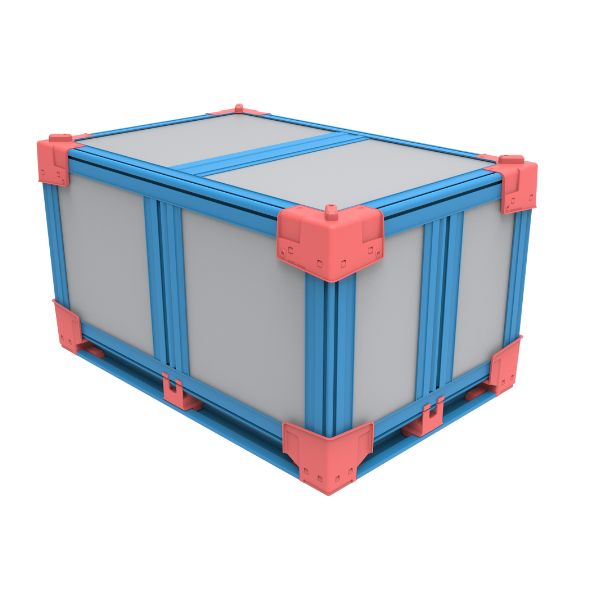

The Innovation in Manufacturing Large Costume-Sized Plastic Boxes

For many years, traditional wooden boxes have been central to packaging and transporting goods across various industries. However, in the modern era, there is a growing demand for durable, lightweight, and sustainable packaging solutions. This shift has led to the adoption of large, custom-sized plastic boxes, such as the EcoBox, which replace wooden boxes. Using plastic for manufacturing large boxes offers significant advantages in terms of innovation, efficiency, quality, and sustainability.

The Innovative Advantages of Plastic Boxes

Customization and Precise Manufacturing

One of the key benefits of large plastic boxes, like the EcoBox, is the ability to produce them in custom sizes, tailored to the specific needs of the customer. While wooden boxes are limited by production processes and materials, plastic boxes can be designed to meet exact requirements, whether in size, shape, or special features like transparent windows, ventilation openings, or removable internal components.

Enhanced Durability and Lightweight

New plastic boxes offer exceptional durability compared to wooden ones. They are resistant to weather conditions, humidity, insects, and rot, making them last longer. Moreover, plastic boxes are lighter than wooden ones, reducing transportation costs and handling labor. The combination of durability and lightweight makes them an ideal choice across various industries such as agriculture, medicine, defense, and high-tech.

Improved Sustainability and Environmental Friendliness

One of the main challenges of using wooden boxes is the constant need for tree cutting. Shifting to plastic boxes reduces the need for logging, contributing to environmental preservation and preventing the depletion of natural resources. Furthermore, plastic boxes can be reused and recycled multiple times, unlike wooden boxes that often wear out and break after a few uses. This reduces waste and leads to long-term economic savings.

Simple and Efficient Preventive Maintenance

Plastic boxes require less maintenance compared to wooden ones. They are not susceptible to rot, mold, or insect damage, thus do not need preventive treatments like wooden boxes. This saves time and resources and reduces ongoing maintenance costs.

Innovation in Design and Performance

Large plastic boxes, such as the EcoBox, are manufactured using advanced technologies that enable sophisticated design and innovative features such as integrated handles, smart locking systems, and removable internal partitions. These features improve usability and enhance work efficiency, particularly in logistics and high-production industries.

Conclusion

The shift from wooden boxes to custom-sized plastic boxes like the EcoBox is not only a technological change but also a strategic move that enhances the efficiency, safety, and sustainability of industrial processes. This innovation allows various industries to benefit from a durable, strong, and flexible

product tailored to their evolving needs while maintaining low costs and environmental friendliness. With these clear advantages, large plastic boxes are becoming the preferred choice across a wide range of fields.