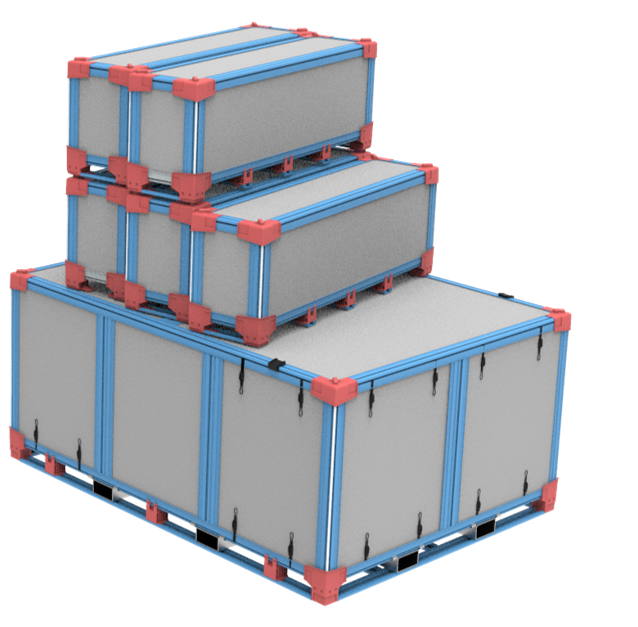

EcoBox supports a comprehensive global reverse logistics operation, offering a seamless and efficient process for managing reusable crates. This service enhances the supply chain by reducing waste, minimizing costs, and improving sustainability. With a network of logistics centers and advanced inventory management systems, EcoBox ensures the reliable collection, maintenance, and re-supply of crates worldwide.

The EcoBox take-back system efficiently collects EcoBoxes from locations worldwide, tackling the complex logistical challenge of achieving global coverage across diverse regions. This is made possible through a robust logistics network comprising 8 logistics centers and 200 warehouses, enabling swift and reliable collection. The EcoBox collection team communicates fluently in all languages and adapts to local cultural nuances, ensuring seamless interactions with customers and suppliers everywhere. The service covers a wide range of end-users, including warehouses, end customers, distributors, and integrators, providing the flexibility to meet each client’s specific logistical needs. This approach minimizes the need for new packaging and fosters sustainability through repeated reuse.

At dedicated maintenance centers, EcoBoxes undergo thorough cleaning and inspection to maintain high standards of quality and functionality. This meticulous process ensures that each EcoBox is fit for reuse, providing reliable protection and performance for subsequent shipments. To complement this, EcoBox offers secure storage solutions through its extensive global network of warehouses. Proper storage optimizes space and logistics operations while protecting the EcoBoxes from damage, thereby extending their usable life. Once cleaned and inspected, EcoBoxes are re-supplied back to customers, ready for continued use. This ongoing cycle reduces the need for single-use crates, supports sustainability efforts, and aligns with companies’ environmental commitments, ultimately enhancing operational efficiency.

EcoBox supports a comprehensive global reverse logistics operation, offering a seamless and efficient process for managing reusable packaging solutions. This service enhances the supply chain by reducing waste, minimizing costs, and improving sustainability. With a network of logistics centers and advanced inventory management systems, EcoBox ensures the reliable collection, maintenance, and re-supply of packaging worldwide. By utilizing multi-use, lightweight, and foldable plastic alternatives instead of single-use, heavy wooden options, EcoBox customers can achieve up to 35% cost savings and a quick return on investment (ROI). This innovative approach not only reduces storage and transport costs but also eliminates the expenses associated with wood waste disposal, further emphasizing the economic and environmental benefits of EcoBox’s offerings.

The Eco-Flow software is a powerful tool for inventory management, enabling companies to efficiently monitor and manage their EcoBox units. With its user-friendly mobile app, the software utilizes barcode scanning technology to provide real-time tracking throughout the reverse logistics process. This capability ensures that all units are accounted for at every stage, streamlining inventory management and enhancing overall operational efficiency. The Eco-Flow system supports logistics managers in maintaining control over their valuable equipment worldwide, allowing them to track the movement and condition of their assets in real-time. By offering a comprehensive overview of inventory, the system proactively prevents shortages of EcoBoxes needed for product transport, ensuring continuous availability and optimizing supply chain operations while minimizing disruptions.

ecobox@ecoboxglobal.com

Our service center is ready to tackle any challenge and provide innovative engineering solutions tailored to your specific needs. Whether you require custom designs, unique features, or specialized logistics support, we are here to help you optimize your supply chain. Feel free to contact us to discuss how EcoBox can benefit your business.